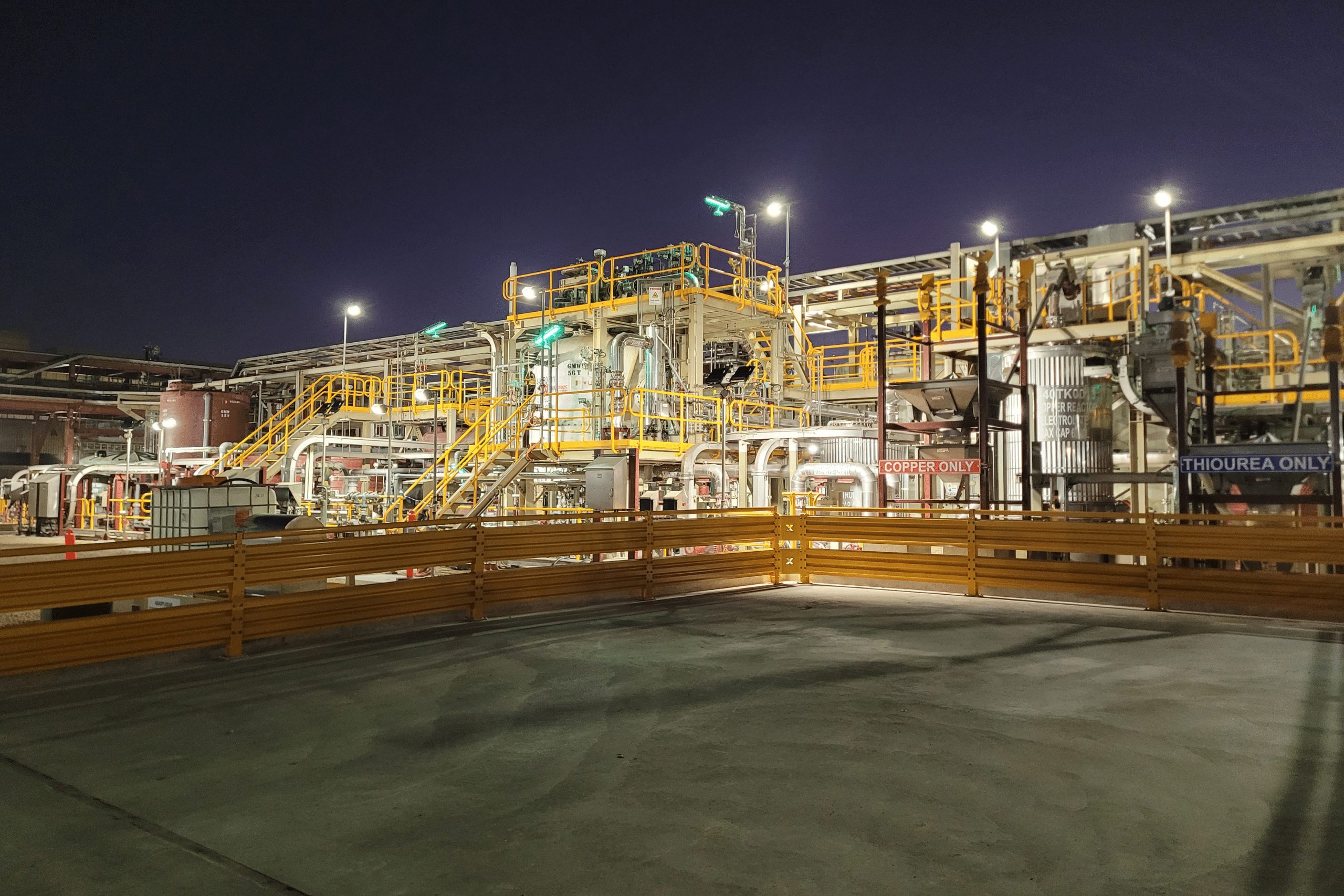

BARS – Olympic Dam

ICE Engineering & Construction was engaged by Kaefer/BHP to deliver Electrical and Instrumentation (E&I) works for the Bismuth and Antimony Reduction System (BARS) Project. This large-scale project required early engineering input, detailed construction planning, and full E&I installation across switchrooms, pipe racks, and process facilities.

Despite ongoing design changes and shifting schedules, ICE Engineering & Construction successfully supported the project through all stages of engineering, installation, commissioning, and handover. The project showcased ICE Engineering & Construction’s adaptability, technical expertise, and ability to maintain strong client relationships while delivering within a high-risk, complex environment.

Scope of Works Included:

- Early engineering support, including constructability reviews and development of construction work packs.

- Installation of underground conduits and earth grid systems in collaboration with civil contractors.

- Completion of switchroom foundation connections, including earthing and supply.

- Cable installation throughout main pipe rack ladder systems and underground conduits.

- Installation of stainless-steel cable ladder and conduits as cable supports.

- Distribution board and junction box installations, with preliminary terminations.

- Power and control cable installation and termination.

- Switchroom alterations and fit-out, including additional cabinets and variable frequency drives.

- Installation of instrument energy source supplies, including pneumatics.

- Preliminary testing, QA verification checks, and Stage 2 testing with BHP commissioning team.

- As-built and as-commissioned drawing mark-ups, alterations, and final submissions.

- Ongoing field technical support through Stage 3 and Stage 4 commissioning

Sector: Mining / Processing

Client: Kaefer / BHP

Cost: $11.7M